What Do Customers Really Want? – True Colour Choice

At ProKolor we believe that providing real choice in both colour and finish will be critical for achieving long-term success in the PVCu windows market. We see this is increasingly what consumers are demanding1) as they focus on aesthetics and decorative trends in upgrading their properties and as they become aware of what is possible from some of the leading PVCu window suppliers. This wide colour choice permeates almost all other areas of lifestyle and home improvements including alternative timber or aluminium window choices, and is something customers are now also seeking when buying PVCu windows.

The latest PVCu window designs offer outstanding aesthetics, based on authentic style and slim line profiles, butt jointing, flush casement and multiple bead and profile shapes, that can truly compete with both the contemporary aluminium and traditional wood products. However, offering these products with a wide colour and finish choice is really not compatible when working with the traditional solution for producing coloured PVC windows, namely foiled PVCu profile. By its nature, this approach is very effective for large volume colours, but is expensive and too slow in meeting demand for low volume and bespoke colours and finishes. In response, fabricators are increasingly switching to paint refinishing of windows prior to final assembly; with larger fabricators installing in-house paint shops and others using subcontract paint services. This use of paint refinishing enables a responsive and cost-effective route to offering a true colour choice to customers and therefore looks set to accelerate as suppliers compete to meet this key area of future demand.

ProKolor supply water-based coatings specifically developed for exterior applications on PVCu windows and other hard plastic construction products. The Zowo-Plast system (ZP 2400 series) is the market leading PVCu coating solution in both continental Europe and the US. The 1K water-based product is AMAA qualified and does not have the safety concerns associated with 2K and solvent-based products. The high-performance and robust ZP 2400 paint system is applied in a single coat to either finished windows or bar length. Developed for process efficiency and with the fabrication process in mind, the 2400 series system is hard while maintaining flexibility and therefore copes with the handling during the fabrication process. The pigments used are highly stable and heat fast meaning there is no concern of the heat fading or changing the colour during the welding process.

ProKolor® works directly with our customers to support them to adopt a true ‘colour on-demand’ operating model that will differentiate them from their competitors and add real value to their businesses; with top line growth, reduced inventory levels and improved profitability. www.ProKolor.co.uk

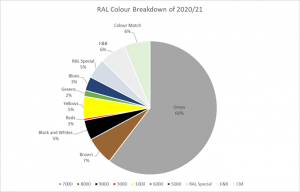

- Demand for Bespoke Colours

We see the high and growing demand for bespoke colours through the wide range of colours that we supply to our customers. For example, the below graph illustrates the breadth of colours supplied to one customer over a 9-month period. 47 different colours in total, with greys (>20) not surprisingly dominating. Noteworthy is that this even includes the popular RAL 7016, 7022 & 7032 for example, which is available in foil stock, but nonetheless some installers prefer a paint finish aesthetic compared to a foil finish. Discerning customers aren’t just interested in colour but also finish, high quality paint can give the customer this turning a uPVC window into a high-end aesthetic product competitive with both aluminium powder coated and Farrow and Ball painted wood windows.

Colour Breakdown:

Full colour selection: